BENDIX TU-FLO 501 AIR COMPRESSOR User Manual

Browse online or download User Manual for Air compressors BENDIX TU-FLO 501 AIR COMPRESSOR. Bendix® TU-FLO® 501 Air Compressor

- Page / 12

- Table of contents

- BOOKMARKS

- 501 Air Compressor 1

- OPERATION 2

- (Supply Reservoir) 3

- REMOVING AND DISASSEMBLY 6

- DISASSEMBLY 6

- OR AFTER EACH 200,000 MILES 6

- GENERAL SERVICE CHECKS 6

- CLEANING OF PARTS 7

- INSPECTION OF PARTS 8

- ASSEMBLY 9

- COMPRESSOR TROUBLESHOOTING 11

- THESE INSTRUCTIONS TO AVOID 11

- PERSONAL INJURY OR DEATH: 11

- TABULATED DATA 12

Summary of Contents

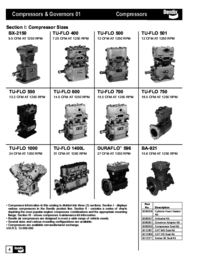

1®Bendix® TU-FLO® 501 Air CompressorSD-01-337DESCRIPTION AND OPERATIONGeneralThe function of the air compressor is to provide and maintainair under pr

10If the compressor uses a ball type main bearing, press theball bearing onto the correct end of the crankshaft. Positionthe ball bearing and the cran

11Position and install the inlet valve guides, then drop the inletvalves in their guides. The inlet valves should be a loosesliding fit in the guides.

126. Never exceed manufacturer’s recommendedpressures.7. Never connect or disconnect a hose or linecontaining pressure; it may whip. Never remove acom

2FIGURE 1 - VARIOUS COMPRESSOR MOUNTINGSFIGURE 2 - COMPRESSOR NAMEPLATED-2 D-3D-1All Tu-Flo® 501 compressors utilize the engine’s pressurizedoil syste

3COMPRESSOR & THE AIR BRAKE SYSTEMGENERALThe compressor is part of the total air brake system, morespecifically, the charging portion of the air b

4DISCHARGEVALVEPISTONSTROKETO GOVERNORINTAKESTRAINERUNLOADERPLUNGERINLET VALVETO RESERVOIRDISCHARGEVALVEPISTONSTROKETO GOVERNORINTAKESTRAINERUNLOADERP

5PREVENTIVE MAINTENANCERegularly scheduled maintenance is the single mostimportant factor in maintaining the air brake charging system.Refer to Table

6EVERY 24 MONTHS, 7200 OPERATING HOURSOR AFTER EACH 200,000 MILESPerform a thorough inspection as indicated below anddepending upon the results of thi

7A convenient method to indicate the above relationship is touse a metal scribe to mark the parts with numbers or lines.Do not use a marking method th

8OIL PASSINGAll reciprocating compressors currently manufactured willpass a minimal amount of oil. Air dryers will remove themajority of oil prior to

9CrankshaftCheck the crankshaft threads, keyways, tapered ends andall machined and ground surfaces for wear, scores, ordamage. Standard crankshaft jou

(32 pages)

(32 pages)

Comments to this Manuals